NEOTEL TECHNOLOGY

Neotel technology provides intelligent and automatic solutions for management of electronic components logistics.

With the use of intelligent shelving or warehouses compact automatic machines, companies will eliminate errors human of wrong pick-up, reducing storage space, order preparation times, guaranteeing quality and traceability.

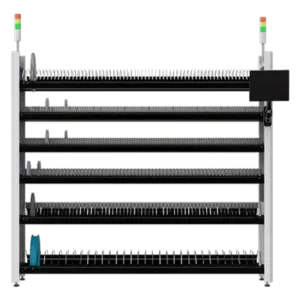

NEO LIGHT

NEO LIGHT system provides an economic solution for material management.

It is a SMT reel storage solution and utilizes “Pick to Light” technology to guide users for SMT components picking/putting. It is helpful when operators are doing SMT Kitting/Replenishment work. With the Same functionality “Neo Light Plus” not only works with Pick to Light technology but also equipping location sensor.

“Pick to light” is a modern picking technology for electronics manufacture that utilizes lights on smart racks or shelves to indicate pick locations and guide users through whatever material check in, job list/work order process, etc.

Unlike the standard NEO LIGHT solution but with the same functionality, you can choose the version “Neo Light Plus” that thanks to the addition of a touch screen and a position sensor, prevents any type of error during the insertion and withdrawal of the reels in the structure.

Neo Light is powered by SMF software. SMF: Smart Material Flow

Smart Material Flow is the software suite from Neotel Technology for controlling and automate electronics materials.

It can cover all your materials needs: Materials receiving, Automated material storage/retrieval system, AGV control, Component counting, Kitting, etc. Neo Light and Neo Light plus store up to 1400 reel per rack.

Are available different versions: “Neo Light Mobile” with mobility feature and “Neo Light Stencil” for SMT stencil storage.

SMD BOX

SMD BOX is designed to minimize and mobilize, digitalize your material stock. We secure inventory, increase productivity and accuracy. The whole system is also driven by SMF and it builds link between production and material flow.

SMD BOX family provides intelligent SMD component storage solution from 800 to 2500 reels.

SMD BOX SISO (Single Input/Single Output) is entry level electronics component storage system, SMD BOX MIMO (Multi Input /Multi Output) can receive stacked reel materials from AGV and a true autonomous system and SMD BOX DUO is dual module system can store up to 2500 reels.

Users just need to put material into SMD BOX.

Smart camera system will be triggered and read the material information whatever in 1D or 2D and real time inventory info. will be updated. Inside robotics arms transfer the materials to assigned location. Material location will be updated to software. In production process, whatever it is for kitting, material replenishment, users only need to send Reel ID, Part number, even job list, work order, SMD BOX will unload required reels at the right time. The whole operation is automated with the help of SMF software.

SMD BOX family are powered by SMF software. SMF: Smart Material Flow is the software suite from Neotel Technology for controlling and automate electronics materials.

It can cover all your materials needs: Materials receiving, Automated material storage/retrieval system, AGV control, Component counting, Kitting, etc.