X-RAY

TECH VALLEY

Techvalley’s history is the history of Korean industrial X-ray inspection system As proved by more than 50 important patent status and intellectual properties.

The company produces 2D, 3D and AXI systems and also the software. With its own technology, Techvalley has developed major core components and products from small and medium-sized inspection systems to high-energy X-ray systems.

Techvalley has been providing various kinds of industrial X-ray inspection/analysis systems for all the industries including metal, electric/electronic, semiconductor, automobile component, secondary battery and container, etc.

2D

The Techvalley 2D X-ray series is equipped with self-image analysis software capable of measuring and analyzing various samples. It is a professional inspection equipment with compact design and user-friendly design. It has the same or advanced detection capability compared to foreign equipment, but it is advantageous in terms of maintenance. As a result, customers can select various models according to the size, material and characteristics of the inspection target and apply them to the production site. Automatically categorize and save captured X-ray images, and achieve the highest inspection speed and accuracy. The world’s highest quality X-ray source and high-resolution industrial detector are applied for more accurate and precise 2D X-ray image acquisition and analysis. It is made by shielding cabinet, which is designed as a double structure, also provides complete shielding of radiation and consideration of user and fields safety.

2D + 3D

The 2D + 3D systems solution incorporates the features and benefits of 2D, 2.5D and 3D inspection. All in one!

The systems included iTOP feature.

The iTOP (Inspection Technology of Overlapped Pattern) inspection is a method that is based on AI Platform technology that can inspect points with a single image, which was only possible after a long period of analysis in the previous 3D CT. Recently, Xray systems are also supplied with the option laminography that creates individual layers through the analysis of images acquired in 2D, rotating with a certain inclination of 360 ¹ on the object to be inspected.

Advantages

- Check the percentage of voids inside the weld joints even at different levels.

- Easily separate the top side from the bottom, especially in the presence of components on both sides, which could compromise the success of the analysis.

- Display the individual layers from top to bottom, front to back or left to right.

The 2D + 3D systems solution incorporates the features and benefits of 2D, 2.5D and 3D inspection. All in one! The systems included iTOP feature. The iTOP (Inspection Technology of Overlapped Pattern) inspection is a method that is based on AI Platform technology that can inspect points with a single image, which was only possible after a long period of analysis in the previous 3D CT.

ARIRANG 160CT The ARIRANG 160CT is equipped with a large area detector that can shoot even 350 large parts at once. As the ARIRANG 130CT model integrates itop options, laminography, 3D graphic rendering software, voids auto inspection and more. Scanning for defects is possible by taking only 90 seconds, so more than 300 CT scans… Continue reading ARIRANG 160CT

AXI

AXI(Automated X-ray Inspection) system is a revolutionary automated X-ray inspection system that has built-in image analysis software and automatically determines the goodness and badness of the inspection sample using the image acquired by the inspection equipment itself. It is optimized for industry and precision parts inspection of mass production system structure requiring full inspection.

Especially, it is X-ray inspection equipment which can perform automatic inspection of in-line. AXI system can be inspected include SMT line mounting parts, mobile phone battery, mobile phone camera actuator ball, LED, speaker and microphone for mobile phone, condenser, USIM tray, semiconductor and automobile ECU board.

The HAWKEYE9020 AXI system is a 2.5D In-Line X-ray Inspection Equipment. It is a revolutionary automated X-ray inspection system that has built-in image analysis software and automatically determines the goodness and badness of the inspection sample using the image acquired by the inspection equipment itself. Automated inspection equipment with overlap resolution techniques such as Laminography Slice CT, i-TOP, and PTH Realization of high-speed inspection of 0.4 to 0.8 seconds per point (depending on type of inspection).

The HAWKEYE9000L is an Automatic inspection equipment for large-sized products such as LED, BLU, etc. Realization of high-speed inspection of 1.5 to 2 seconds per point (depending on type of inspection) Use Gerber files for easy programming, making it one of the best-selling in the lighting industry.

CHIP COUNTER

There are many kinds and variety in a reel chips. Conventional mechanical manual counters have the disadvantage of being time-consuming and less accurate. Techvalley has developed the world’s first automatic reel chip counting equipment using X-ray in 2013, and now produces and delivers 4th generation models as of 2017. It can count reels of various sizes, and boasts counting speed of 13 seconds for 180mm. The use of an AI (Artificial Intelligent) algorithm and the connection to a single database in continuous updating guarantee the automatic, effective and accurate recognition of all the components on the market.

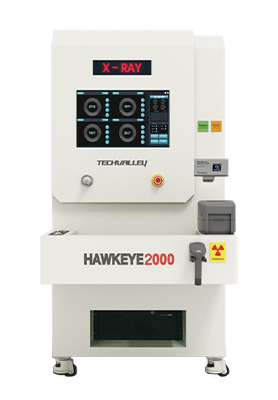

HAWKEYE2000 The HAWKEYE2000 only needs one button to count various components automatically in a few seconds. It can also count up to four reels (180 mm) simultaneously. Various chips and components are counted, with the results sent directly to the SMD material management server (ERP system). Also during this process,…